We provide 3D printing in Adelaide for clients all across Australia.

Our 3D printing services

Looking for 3D services in Adelaide? We have an amazing array of 3D printing solutions for your business or project. We have the expertise and technology to meet your exacting requirements, and the right materials to produce high-quality, high-strength parts, products and prototypes.

And with Coiltek Electronics, the process is straightforward, efficient, and affordable.

With our state-of-the-art 3D printers – including the Markforged X7 – we can quickly and affordably produce quality, high-strength functional parts for prototyping and end use.

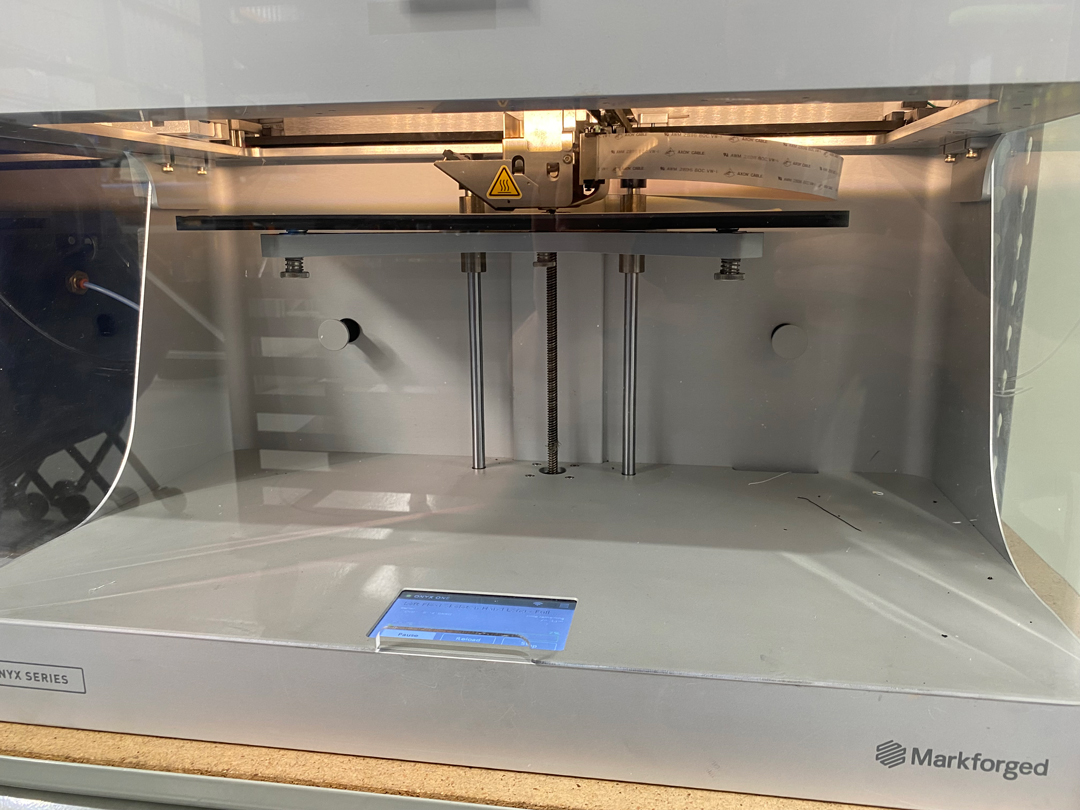

Markforged X7 3D printer

Get industrial-grade parts in hours, not weeks. With the Markforged X7 3D printer, your engineering and design team can manufacture faster than ever before.

Stronger parts

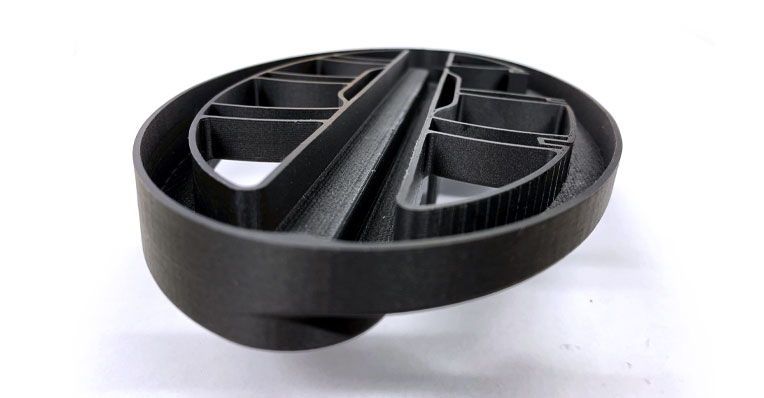

The X7 prints continuous carbon fibre reinforced parts that are as strong as (and capable of replacing) machined aluminium. It also prints in a variety of materials including Fire Retardant, Anti-Static Nylon and ONYX

Flexible functionality

The Markforged X7 3d printer has an industrial material or print mode ideal for fabricating functional flame and chemical-resistant, energy absorbent, high-resolution and draft parts.

Reliable & accurate 3D printing

With advanced accuracy and reliability, precision-machined hardware, advanced sensors and a unique software drive, the X7 offers micron-level laser scanning for closed-loop calibration – consistently producing parts with a near-perfect surface finish.

Specifications

Print workspace: 330mm (w) x 270mm (l) x 200mm (h)

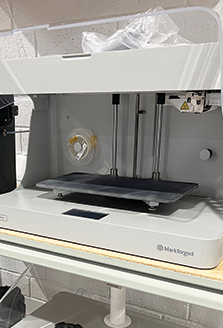

Markforged Onyx One 3D printer

The Markforged Onyx One 3D printer is perfect for smaller units that need to be reinforced with fibreglass.

Superior strength

With an incredible tensile strength, the Markforged Onyx One 3D printer prints at almost double the strength of 6061 alloy aluminium and 20 times the strength of normal ABS plastic.

Specifications

Print bed size: 320mm x 132mm x 154mm

Z layer resolution: 100um – 200um

Printing process: Fused filament fabrication and continuous fibre reinforcement

Materials: Composite base filaments & fibreglass

Markforged Onyx Pro 3D printer

Get stronger, stiffer and more accurate parts with our Markforged Onyx Pro 3D printer.

Industrial-grade performance

Featuring an all-aluminium unibody enclosure built around an ultra-flat gantry system, the Markforged Onyx Pro 3D printer comes complete with kinematic bed coupling and a precision ground print platform, bringing you impressive quality and affordability.

Superior materials

Onyx plastic is 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fibre, making it suitable for anything from tooling and fixtures to end-use parts. Combining nylon with chopped carbon fibre, the 3D printer offers very strong thermoplastic with fantastic heat and chemical resistance, and an ideal printing resolution for a smooth and accurate finish.

Specifications

Print bed size: 320mm x 132mm x 154mm (12.6” x 5.2” x 6”)

Printing resolution: 0.1mm

Onyx plastic: 1.4 times stronger than ABS

FAQs

Oven Curing

As well as 3D printing in Adelaide, we also offer oven curing with our 2000-litre convection oven. It can be used for epoxy curing and transformer potting and curing with low or high temperature lacquers (max 150°C). This prevents movement from the winding wires, and produces more accurate results in applications requiring higher tolerances.

A multi-layered stainless steel trolley rack can cater for small or large volumes and can also be used for any cable curling applications or requirements.

Get in touch to find out more about our higher temperature curing or curling.